MbDFEM Simulation of the Oblique Pin Pendulum.

Problem description.

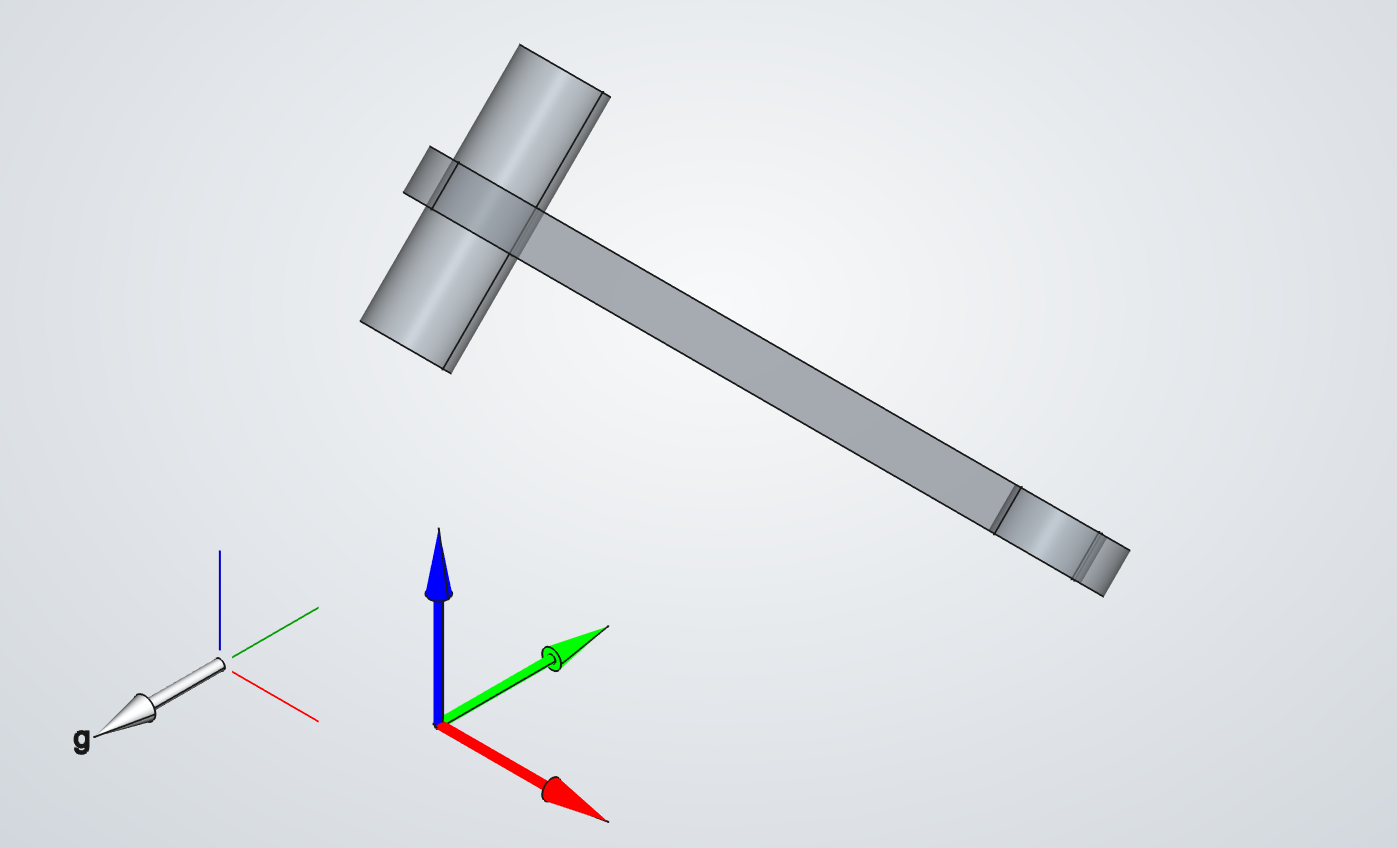

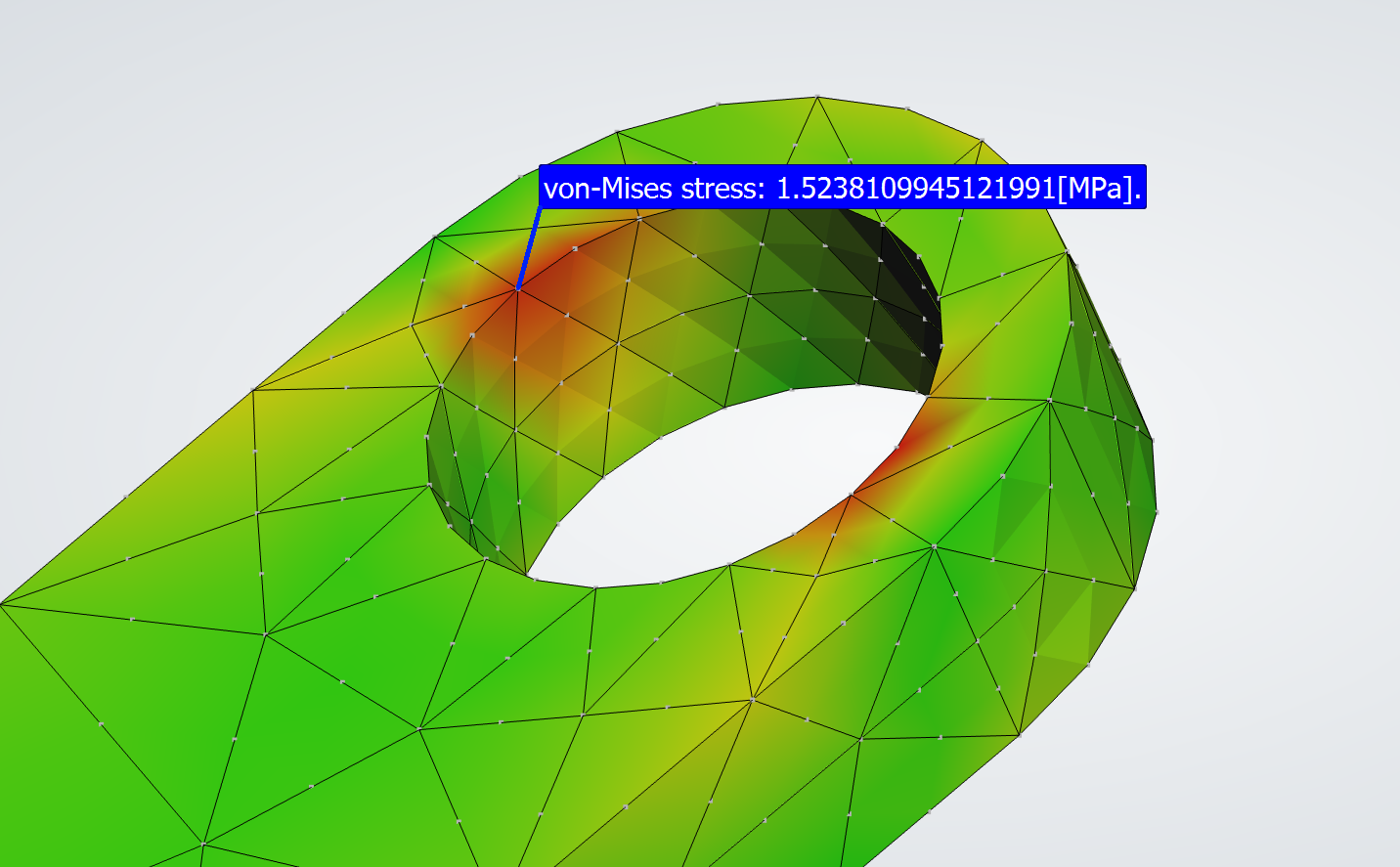

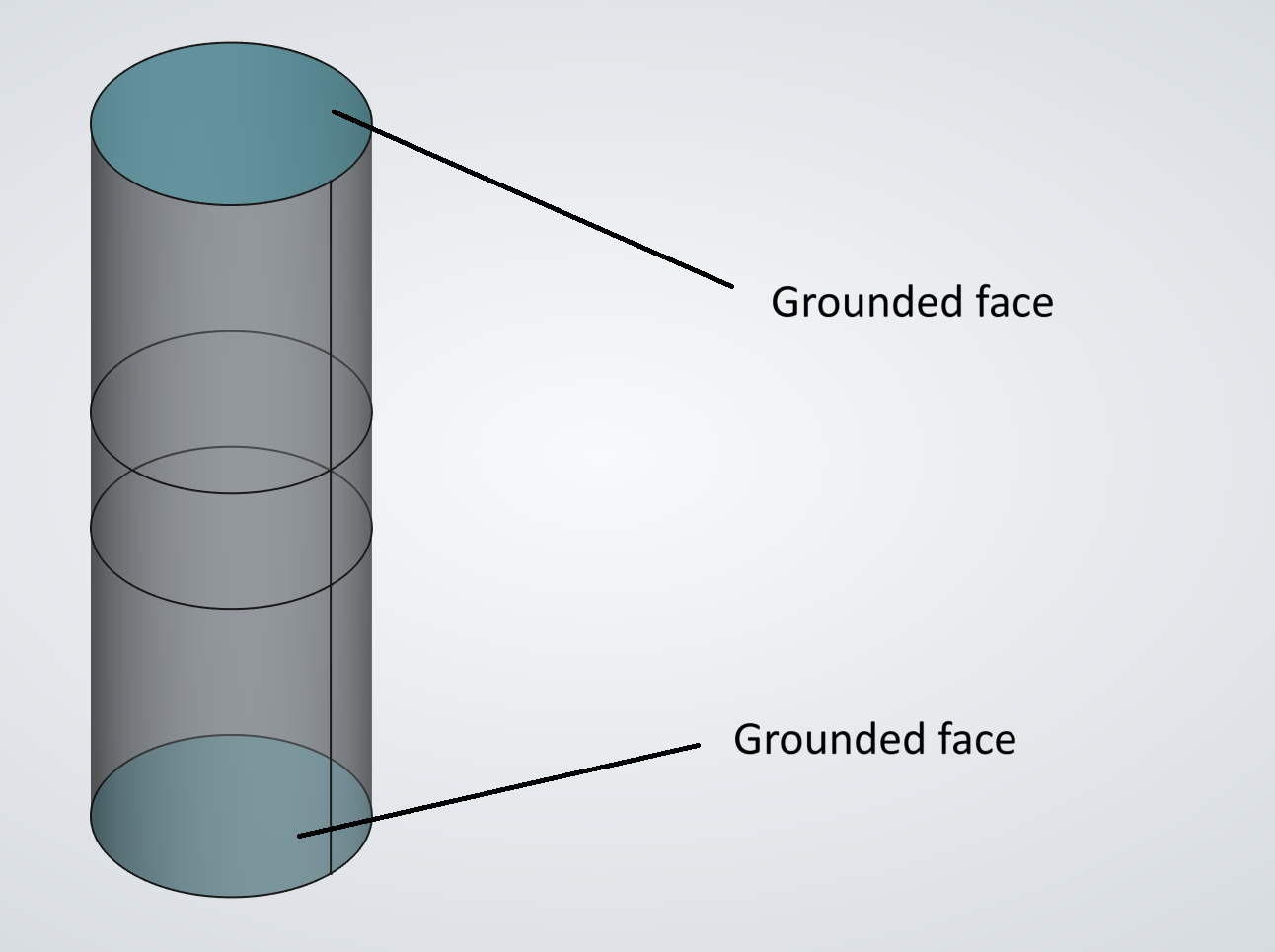

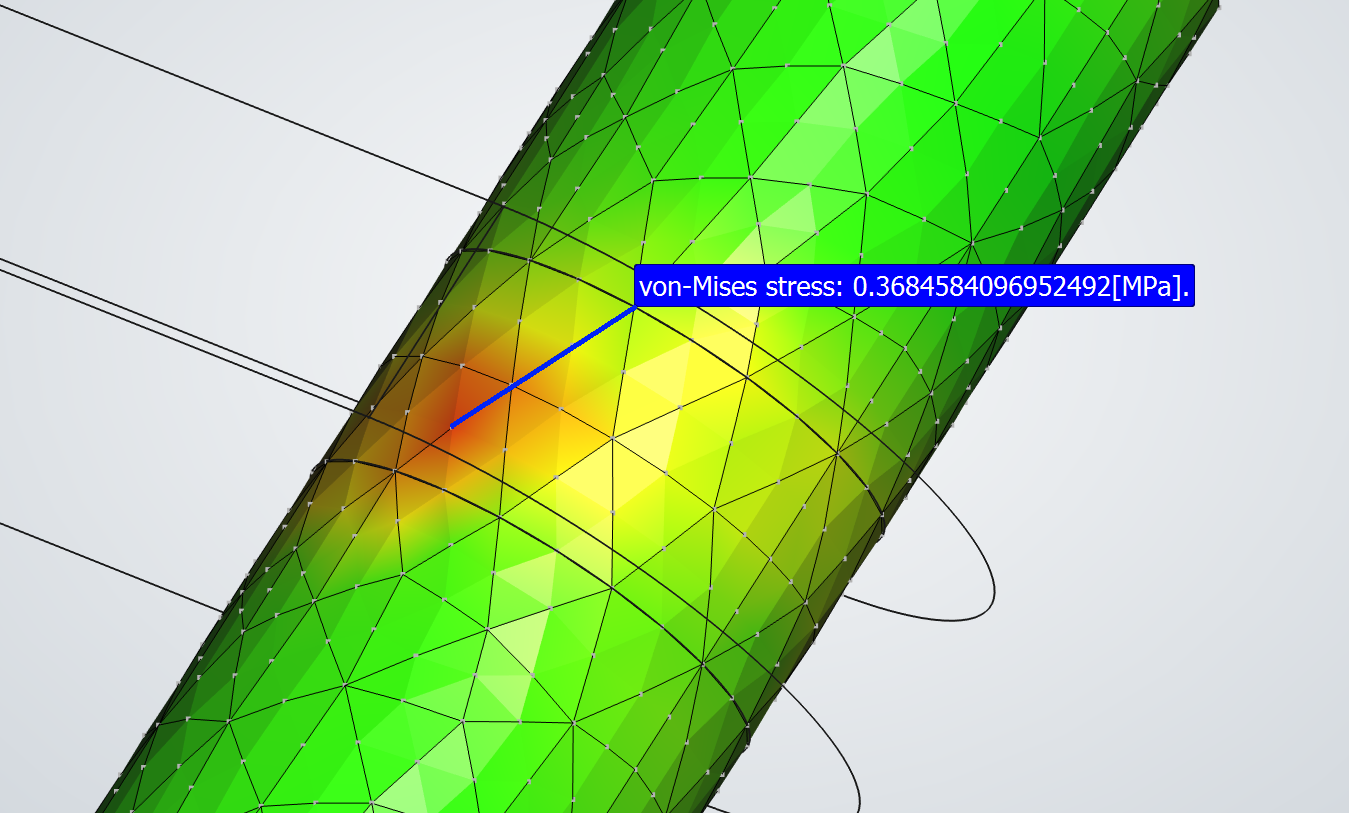

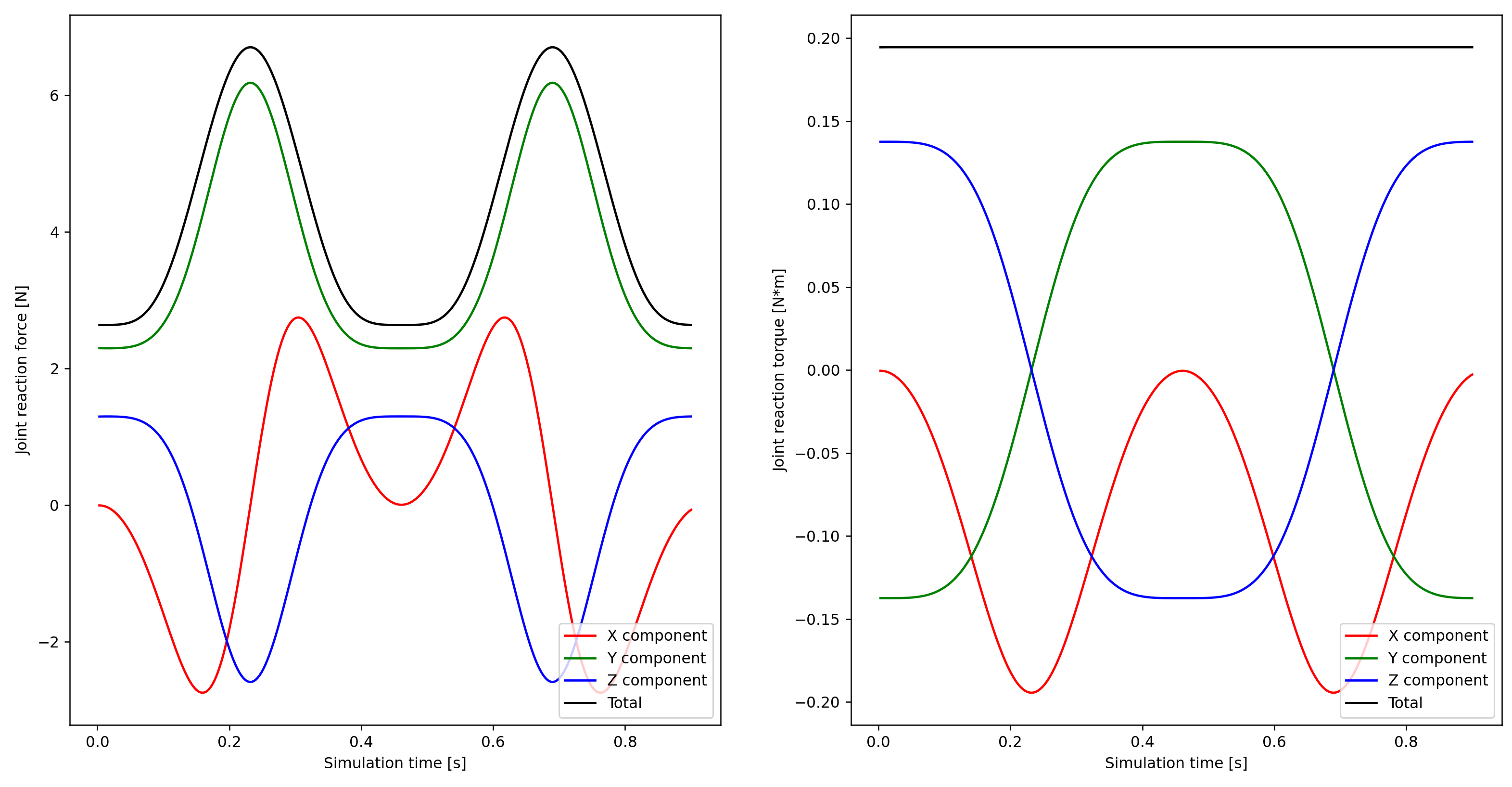

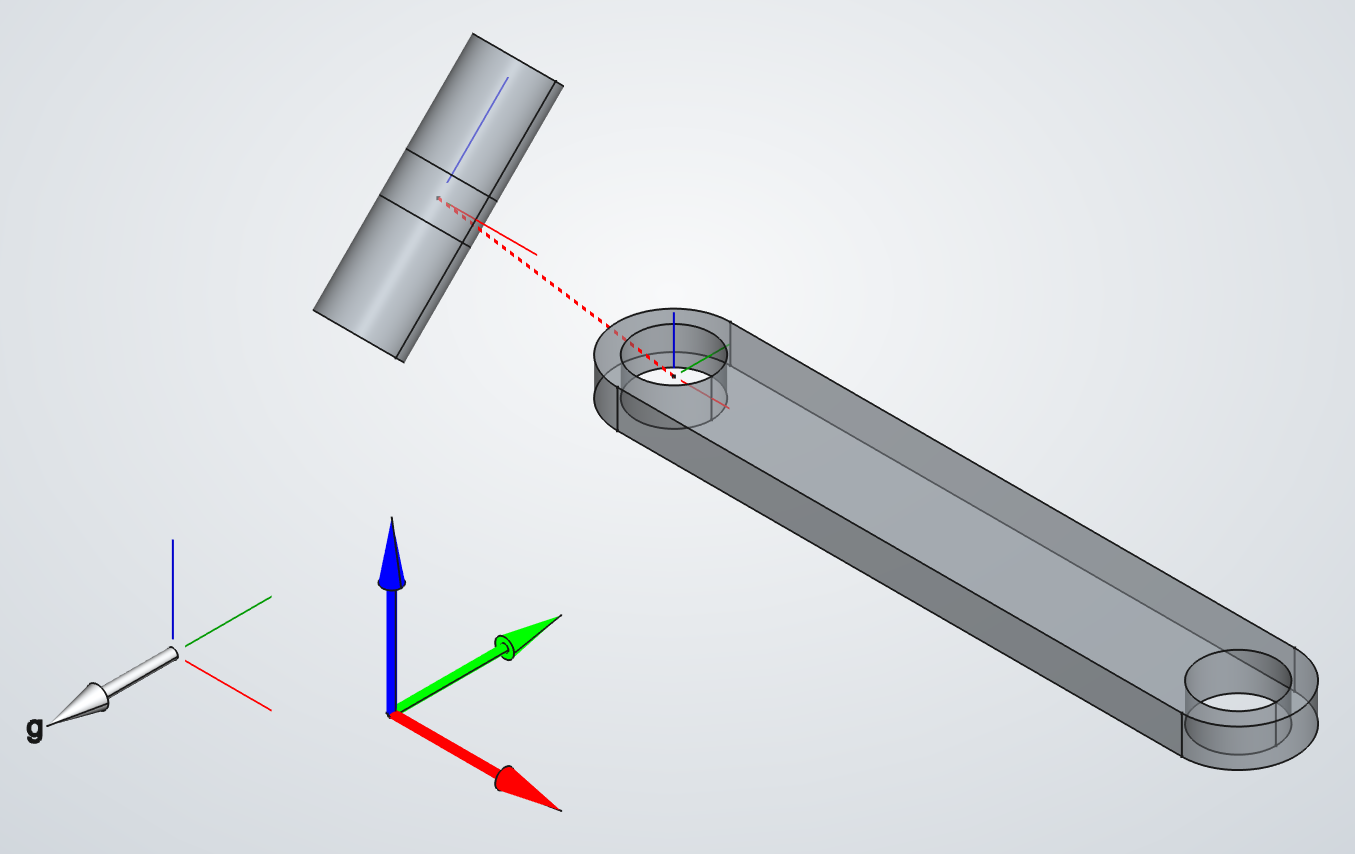

In our Simple Pendulum example, the direction of the hinge joint Z axis (the rotation axis), was perpendicular to the gravity vector. Thus, the hinge joint torque was zero, and there were no FEM loads derived from joint torque. In this example, the pin is rotated 45 degrees about global X. The image on the left shows the exploded assembly of this new configuration. The image below shows the solved assembly. The direction of gravity is shown in both images. The dimensions of the parts are the same as in the Compound Pendulum simulation.